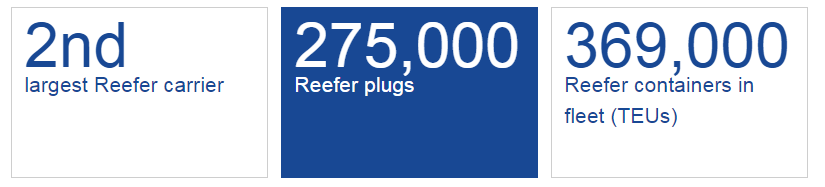

With over 369,000 containers (TEUs), CMA CGM owns the second largest fleet of Reefer containers in the world.

Designed for the transport of perishable goods in a temperature controlled environment, these containers come in different sizes and are equipped with the latest technologies.

Our Reefer equipment

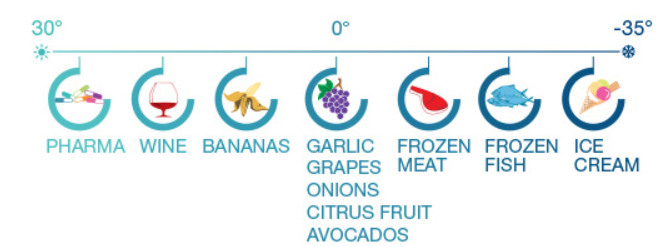

The CMA CGM Reefer fleet consists of 20’, 40’High Cube and 45’32/33 Pallet Wide containers allowing the transport of goods at temperatures ranging from -35°C to +35°C.

With an average age of five years, the Reefer fleet is one of the youngest in the industry.

Warning : all technical data given for these containers are non-contractual data. They do reflect the majority of our container fleet but are non-exhaustive and given as examples.

As such, the group cannot always ensure the availability of containers with the subsequent specifications.

How does a Reefer container work?

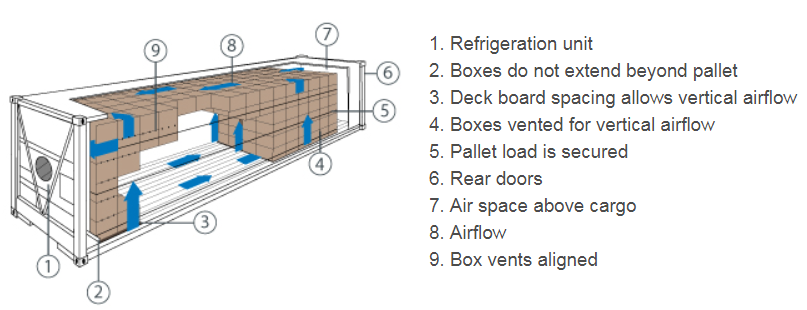

All CMA CGM Reefer containers are bottom air delivery units designed to distribute chilled air from the floor, via specific T-shaped decking, with the advantage of producing a

consistent and uniform flow of air across the entire shipment, powerful enough to ensure a perfect air exchange with the goods.

The powerful refrigeration units can maintain or lower the temperature your shipment, even in the most difficult conditions. Each unit is also equipped to ‘warm up’ the goods for

those shipments where required, with the ability to maintain temperatures up to 35°C when required, regardless of outside temps.

Controlling the temperature

- Frozen mode : temperature control is accurately achieved through the return air.

- Chilled mode : temperature control is accurately achieved through the supply air flow.

Ventilation

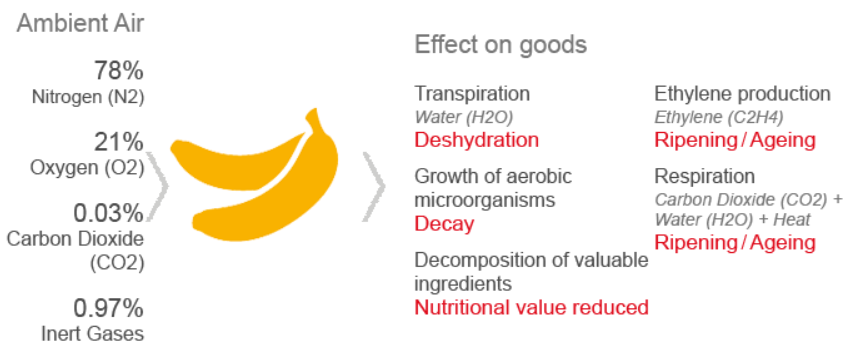

Forced circulation of cool air prevents chilled products from ripening too quickly, ensuring a longer shelf-life and maintaining the market value. In order to remove the unwanted gas

and moisture generated by respiration (which can affect quality of the products), fresh air can be exchanged at the rate of 0 to 260 m3/hour, depending on the requirements and the

kind of Reefer used. The airflow is directly influenced by the stuffing and cargo placement in the Reefer container.

This is why packing goods properly is very important. Learn more about cargo handling best practices.

Features & technologies

Controlling atmosphere

Modifying the nature of the air in the container (specifically CO2 and O2 levels) significantly slows down the ripening process of fresh produce and lengthens the storage period.

CMA CGM is able to provide various types of technologies developped by manufacturers (AFAM+, Liventus, Purfresh, Xtenfresh, Star Cool CA).

Controlling temperature

Most perishable goods require a very specific temperature to preserve their quality during transport. CMA CGM Reefer containers can control the temperature and also provide

the following features:

> Higher freezer

High freezer containers are ideal for products (ice-cream and frozen fish) which require extremely low temperatures (down to -35°C). Preserving the cold chain, this container allows

the shipping of otherwise highly perishable goods anywhere in the world.

> Cold Treatment

Cold Treatment is a highly precise process where goods (usually fruits) are kept at a specific and accurate temperature for a predetermined, uninterrupted period. This treatment

ensures the removal of possible parasites (fruit flies and larvae) without requiring pesticides or fumigation. Most importers are required to use Cold Treatment for regulatory reasons.

Set period of cold treatment and set point are under the responsibility of the shipper’s decision according to local regulations. (These sets depend on POD regulation, kind of pest

treated, and country of origin.)

> Multi-temperatures

Multi-temperatures system is used for some commodities, such as tomatoes or potatoes that may require temperature changes during the voyage (up to six different temperatures

can be programmed). The Principle of Multi-temperature is to apply different temperatures during the same voyage. Periods’ settings are defined by the customer in order to obtain

the right ripening for sensitive fruits.

Controlling humidity

Humidity control means dehumidification. Humidity is a quantity of water found inside the air, very small drops of water suspended within.

Humidity comes from the evaporation from the cargo itself or from the air entering the Reefer through the opened fresh air exchange system (ventilation).

Various products require a reduced level of humidity inside the container. CMA CGM Reefer containers are equipped with a system capable of controlling the humidity within the range

of 95% to 55%.

Continuous monitoring

> During the journey

CMA CGM’s Reefer experts monitor the containers at every stage of the journey to ensure they are functioning correctly:

- On entering and leaving the container yard

- When being loaded on to a train or truck

- When parked in the port terminal

- During the voyage on board ship

Throughout the journey, CMA CGM staff regularly monitors the Reefer containers using an electronic microprocessor and data-loggers, which record all parameters even when the

Reefer is unplugged.

The data-logger gives us information on:

- Supply air temperature

- Return air temperature

- Ambient temperature

- Cargo temperature (optional)

- Humidity level

Other actions which could impact on the quality of the merchandise are also monitored and recorded:

- Tuning operations

- Modifying the parameters

- Interventions

- Breakdowns

- Alarms

> Modem

A large majority of the units in the CMA CGM Reefer fleet are equipped with modems, providing constant communication with the ship’s bridge. In case of problem, an alarm signal

immediately alerts the technicians ensuring a quick action.

Very Sensitive cargo

Some products require special care because of their impact on the environment, human or animal health. This segment of the market

Some products require special care because of their impact on the environment, human or animal health. This segment of the market

is vast,and ranges from pharmaceutical products to frozen fish.

Our expertise with these products has led to special processes to ensure safety, correct handling and special care:

– To the equipment before it is released to our customers to make sure it fits to the cargo requirements

– To the entire transportation chain according to the customers’ requirements to guarantee the quality of the goods.

Adapted containers

In addition to its maritime offer, CMA CGM provides its customers with a comprehensive door-to-door service and tailor-made inland solutions (rail, road and river) for seamless

continental connections.

Gensets

To guarantee that the “cold chain” remains intact throughout the journey, CMA CGM Reefer containers need a permanent supply

To guarantee that the “cold chain” remains intact throughout the journey, CMA CGM Reefer containers need a permanent supply

of electricity. On board they are plugged into the vessel’s supply and on the quay into that of the terminal.

Those going by road (rail or truck) are equipped with portable generators called gensets.

Containers 45’ and 33 Euro Pallet Wide

CMA CGM has 45’ Pallet Wide and 33 Euro Pallet Wide Reefer Containers adapted to multi-modal transportation, allowing a

largest number of pallets to be loaded.